MFL (MAGNETIC FLUX LEAKAGE)

From the moment metal is worked, it is subject to flaws, deterioration, or other forms of loss. For any industrial asset, corrosion is a particularly significant threat, weakening the integrity of the entire structure, and, if not detected and monitored, creating irreparable damage. It can be introduced in many ways and at any point in an asset’s lifecycle, creating a constant need for monitoring and detection methods. In addition, corrosion does not discriminate. It flourishes in a variety of environments, including oil and gas pipelines. From general wall thinning/erosion to gouging to complex corrosion clusters, various measurement technologies make the location, size, and classification of any type of corrosion defect possible. CO operates the largest fleet of corrosion detection tools in the industry. Paired with a variety of integrity assessments, the following technologies, either individually or in combination, assist in managing the risk presented by this overwhelming threat:

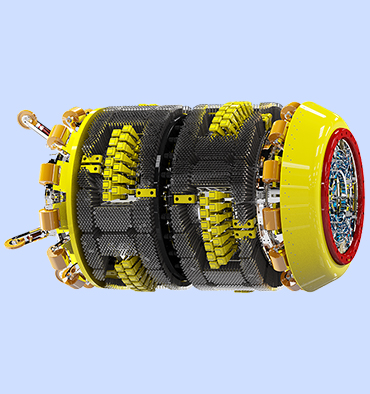

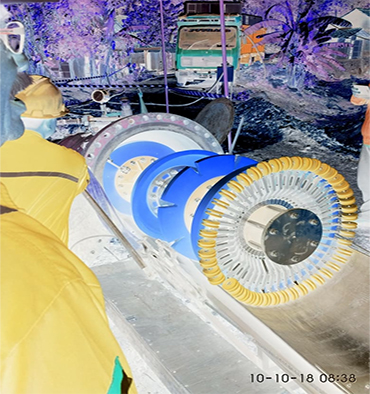

The power horse technology in terms of metal loss detection is based on the high-resolution Magnetic Flux Leakage (MFL) method. State-of-the-art permanent magnets are used to magnetize the pipe wall to saturation level in the axial direction (typically 10kA/m - 30 kA/m). Achieving a high magnetization level is essential to differentiate corrosion from other pipeline features like inclusions and surface defects.

Under normal conditions (no flaws present), the magnetic flux can travel through the pipeline undisturbed. In the presence of internal or external metal loss, the flux “leaks” out of the pipe wall and is recorded by hall-effect sensors. The hall sensors are oriented within the magnetic field and provide coverage of the entire circumference.

The character, amplitude, and various other measurements of the sensor signals are used to determine the depth, length, and width of the detected metal loss.

Technology Benefits:

- Accurate and precise feature classification and sizing

- High magnetization for high quality of data

- Best accuracy in feature length measurement

- Reduced tool dimensions and better inspection reliability as sensors are integrated into a single sensor unit

- Safe negotiation of dual- and multi-diameter pipelines, 1.5D bends and ID reductions up to 15% ID

- Wide range of tools (sizes from 3" to 56" available)

- Applicable in both liquid and gas medium

InTEGRITY RESEARCH LABS also offers the market leading MFL technology, which is able to detect even the smallest pinhole. In addition, the use of Auto Data machine learning algorithms allows for a high level of automation, thereby reducing the “human factor” impact.

TFI

Transverse Field Inspection technology is also magnetic flux leakage based. However magnetizer sections installed in the inspection tool induce a flux field in the circumferential direction

This magnetizer system design ensures detection and sizing of general type metal loss anomalies, same as conventional MFL tools, however it is also specifically developed for measurement of longitudinally oriented anomalies such as tunnel corrosion, longitudinal weld anomalies.

TFI tools also show good performance in detections and sizing of some types of crack-like anomalies. Thus TFI technology ensures detection and sizing if certain anomalies that conventional axial MFL technology has difficulties with, but on the contrary, TFI’s capabilities on circumferentially oriented anomalies are more limited.

InTEGRITY RESEARCH LABS is providing TFI services all over the world on all pipeline sizes. Inspection equipment these tools can be optionally equipped with IMUs to simultaneously carry out pipeline mapping. These tools are equipped with the measurement systems with the highest effective resolution both axial and circumferential ensuring the best sizing accuracy within the natural limitations of magnetic inspection technology

InTEGRITY RESEARCH LABS has unrivalled experience in interpreting in-line inspection (ILI) data, providing fitness-for-purpose (FFP) assessments and crack growth analysis. InTEGRITY RESEARCH LABS helps its customers minimize costs – without compromising operational confidence and quality.

GEOMETRY

Changes in the shape of a pipeline come in two basic forms. There are local features such as dents, ovalities and wrinkles, and there is bending. In most cases, deformation is caused by external influences: either natural phenomena, such as landslides, or accidental third-party actions, such as impact by excavation machinery. While pipelines are very tolerant of deformation damage due to the inherent ductility and toughness of steel, the high stresses and strains caused by these features can compromise integrity and result in failures, particularly when they are combined with other anomalies like gouges, corrosion or weld flaws. Severe deformation can also result in flow restrictions or prevent the passage of cleaning and inspection tools. Therefore, reliable means for identifying, locating, quantifying and assessing these changes in shape are critical for all pipeline operators.

This magnetizer system design ensures detection and sizing of general type metal loss anomalies, same as conventional MFL tools, however it is also specifically developed for measurement of longitudinally oriented anomalies such as tunnel corrosion, longitudinal weld anomalies.

In our networked and GPS-enabled world, we all take location information for granted. For many pipelines built before the days of satellites, construction survey records have been lost, and so the position is not known accurately. Rapid response to critical defects requires accurate information on the position to make sure that the right location is excavated. Cost-effective planned maintenance requires detailed data on the anomaly location. Understanding and managing geo-hazards requires a clear understanding of the transitions between stable and moving ground. Consequently, reliable information on the position of features in a pipeline, the position of the pipeline and changes in position is of great importance to all pipeline operators.

InTEGRITY RESEARCH LABS operates the largest fleet of geometry and mapping tools in the industry, paired with a variety of integrity assessments the following technologies individually or in combination assist in managing the risk presented by this threat:

XYZ MAPPING

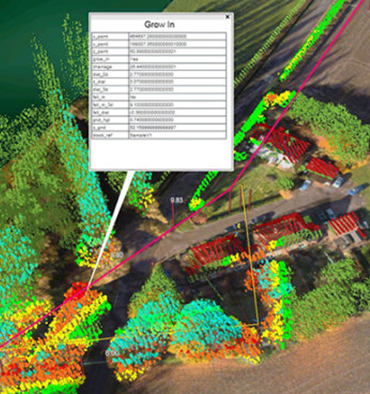

Optimized XYZ Mapping Technology using integrated Fiber Optic Gyroscope and micro-electronic mechanical systems (MEMS) gives precise location and curvature data that can be used in geographic information systems, stress modelling and movement analyses.

Our high-resolution mapping services provide precise information on the pipe route that can be integrated into the customer’s GIS. The InTEGRAGeo XYZ service is a cost-effective way of producing pipeline drawings when original construction drawings may not be available. The tool can run through remote and inaccessible areas where conventional above-ground mapping surveys are impractical. In addition to providing information on the pipeline's position, InTEGRAGeo XYZ data serves as the basis for performing bending strain and pipeline movement assessments. These services are critical for addressing areas where the pipeline may have been influenced by ground movement such as landslides or settlement, or anchor strikes in offshore waters. When combined with other in-line inspection services, the InTEGRAGeo XYZ service provides critical data necessary to properly address pipeline buckles or depth of cover.

A gyro survey measures and maps the pipeline in three dimensions to give a precise depiction of its route and profile. A gyroscopic inertial measurement unit (IMU) on-board an inspection tool measures angular and linear velocity changes in the X, Y and Z axes as the tool moves through the pipeline. Gyro inspection enables the coordinates for girth welds and features to be calculated and recorded while also determining the radius of bends and identifying any departures from the as-built condition

Technology Benefits:

InTEGRITY RESEARCH LABS have mapping tools in the industry, can map and assist in managing the pipeline for future.

- Provision of precise centre line data

- Identification of areas of high bending strain and movement

- More efficient planning of field activities like maintenance work and field verifications

AGM (Above Ground Marker)

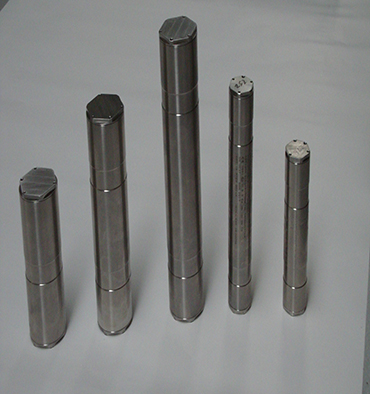

InTEGRITY RESEARCH LABS is providing AGM (Above Ground Marker) for MFL Inspection, to detect the Tool position in Pipeline also give the GPS location of the pipeline.

The Above Ground Marker (AGM) is powered by 4, C cell alkaline batteries that provide an average of 2.5 weeks run time. Using high reliability technology, it detects and records 22Hz and/or magnetic pig passages to GPS synced UTC time. The collected data can be easily downloaded and analyzed while in the field or at the shop with a laptop and USB cable.

Because pipelines run through some of the most diverse and extreme terrains, InTEGRITY RESEARCH LABS AGM is designed for both durability and high performance. In addition to being extremely lightweight and compact in size, The AGM is waterproof and can withstand temperatures over 120 degrees, and under -10 degrees.

InTEGRITY RESEARCH LABS Above Ground Markers are available for sale or rent.

GEO-GAUGE

InTEGRITY RESEARCH LABS is providing GEO-GAUGE is an advance version of GAUGING tool, that can be detect the exact position of reduction while Client GAUGE the pipeline before go for PIGGING tools.

It’s a single Section tool that can provide Geometry + Gauging, it benefits for all that wants upgraded version of Gauging Tool.

COMBO TOOL

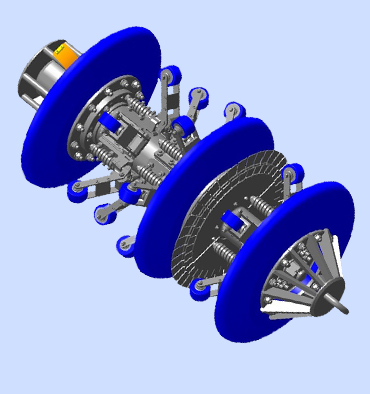

InTEGRITY RESEARCH LABS is providing COMBO TOOL, it is getting more and more common that pipeline operators require receiving maximum data output from a single run. We are ready to respond to that having an effective solution – combination of measurement systems based on different technologies on a single inspection tool.

Our COMBO tools normally combine GEO and Magnetic measurement systems; however we can satisfy any specific request and provide a custom combination due to modular design concept.

Regardless which technologies are used, the received data from both measurement systems is synchronized online during the run for better presentation and faster analysis.

Other SERVICES,

PIG LOCATOR and TRANSMITTER

InTEGRITY RESEARCH LABS has unrivalled experience in interpreting in-line inspection (ILI) data, so we will provide the clients to locate the position of Tools by using our PIG LOCATOR AND TRANSMITTER.

DATA LOGGER

InTEGRITY RESEARCH LABS is providing DATA LOGGER for logging the pipeline condition in run of pig

Cleaning the Pipeline

InTEGRITY RESEARCH LABS is providing cleaning the Pipeline services also. A cleaning pig or poly pig in the pipeline trade is a device much like the smart pig, but "dumb" (without the technology) that simply has a brush, scraper or something similar to clean the pipes. These pigs are specially made to remove sedimentation and build-up that can impede the flow of materials. The type of poly pig used depends on the amount of sedimentation build-up in the pipe. Generally, a strategy of progressive cleaning is implemented using a softer poly pig to begin the process moving to more abrasive pigs in later stages

These types of pigs are not just found in oil and gas, but also are used in other industries that utilize pipes to transfer materials such as paint, chemicals, types of food processing and more.

Cleaning pigs are very important in multi-product pipelines where one pipe is used for the transference of multiple types of materials. In this situation the pig would be used at the beginning and at the end of a cycle to clean the pipes before another material is transported to prevent cross-contamination.

Sales and Lease of Pigging Tools.

InTEGRITY RESEARCH LABS is providing all types of tool sale and lease for Client in Timely manner. InTEGRITY RESEARCH LABS allows customers the flexibility to choose from a collection of service options tailored to their individual needs.